In October, I had the pleasure of joining the Sustainable Cotton Project on a farm tour to see how this non-profit that is dedicated to the production and promotion of of sustainably grown domestic cotton fiber is working to change cotton production in California.

California cotton has the reputation for being among the finest quality in the world. The San Joaquin Valley’s warm springs, hot summers and dry falls are well-suited for growing cotton, producing extra long, strong, and silky fibers. In California, cotton is grown mostly in the San Joaquin Valley, primarily Fresno, Kings and Kern County.

California is frequently the second highest producing state in the U.S., behind Texas, but the acreage in California produces impressive yields of 1,200 to 1,300 pounds per acre, about twice the average U.S. yield.

California grows two types of cotton: pima and a special type of upland cotton called acala. California produces approximately 90% of the nation’s pima cotton deemed the ‘Cadillac’ of U.S. cotton.

Cotton has been grown in California since about 1910.

Cotton acreage was at its height in the 1950s and 1960s with growers cultivating more than one million acres annually.

However, over the years, cotton acreage has been replaced by other crops, such as tree crops, grapevines, and alfalfa. Cotton acreage fell to near-record lows in 2009, but has rebounded recently due to increasing world demand and rising commodity prices.

Cotton is typically planted in April. The cotton boll in its first stage is called a ‘square’ (not pictured). In June, the plant starts to bloom.

After the flower is fertilized, the fiber starts to grow around the seeds to form the cotton boll. A boll is considered a fruit because it contains seeds.

The average cotton boll contains about 500,000 fibers of cotton, and each plant may grow up to 100 bolls.

Once the cotton boll has matured, it opens up to show the fiber. The cotton plants are dried out in preparation for harvesting, usually in October.

While cotton can be grown in some parts of the country without irrigation, all cotton in California is irrigated. Most use furrow irrigation, although drip irrigation is becoming used more frequently. Rising water costs have spurred innovative solutions, such as deficit watering, whereby withholding water at non-critical points in the growth cycle and supplying water at critical times can suppress leaf growth and encourage the the formation and growth of cotton bolls, and can actually increase cotton yield while reducing water consumption.

Cotton is a moderate water user, accounting for less water consumption than almond and pistachio trees, grapevines, and stone fruits, and considerably less than alfalfa.

Cotton is a also crop known for its chemical use, accounting for 10% of pesticide use and 25% of herbicide use worldwide each year, according to the Pesticide Action Network, and many of the most common cotton pesticides have been linked to serious health problems, as well as toxicity in water, air and soil. The Sustainable Cotton Project is working with growers in the San Joaquin Valley to change that, with the goal of lessening the toll that cotton production takes on environmental resources as well as the health of the people who live and work in cotton growing areas. Farmers enrolled in the Sustainable Cotton Project shun the use of 13 of the most toxic chemicals used in cotton production,using biological methods instead. Below, Dr. Pete Goodell, a cotton specialist with University of California Integrated Pest Management, explains how beneficial insects are used to drastically reduce pesticide usage on cotton crops and the role that trap crops and hedgerows may play in diversity and the supply of beneficial insects.

Luis Gallegos, Sustainable Cotton Project field scout, uses a sweep net to look for pests and beneficial insects.

Luis sweeps each field 50 times in three different areas each day, and reports on the numbers of pests and beneficial insects are in the field. If pests are found, biological methods are used as a first line of defense. By employing these methods, growers have been able to reduce their application of chemicals up to 72% as compared to conventional cotton growers.

Farmers enrolled in the Sustainable Cotton Project plant hedgerows with trees, shrubs, and perennial grasses around the farm fields to increase biodiversity and beneficial insect activity, as well as help with weed control and provide protection against soil erosion.

The Sustainable Cotton Project is also experimenting with growing colored cotton. Colors can be produced such as red, green and brown which produces a colored cotton fiber that will not fade.

The yield for colored cotton is lower, and the fiber is shorter and weaker. However, the fiber feels softer and contains no chemicals, bleaches, or artificial dyes.

Cotton is harvested in the fall, usually in October. Due to the high cost of labor, cotton grown in the United States is harvested by machine.

Here is a harvester working the field.

When the harvester gets full, another truck, called a “Boll Buddy” drives up alongside and the load is transferred from the harvester to the “Boll Buddy”.

The “Boll Buddy” empties the load into another machine …

which packs the harvested cotton into squares called ‘modules’.

The harvested modules each weigh about 18,000 pounds.

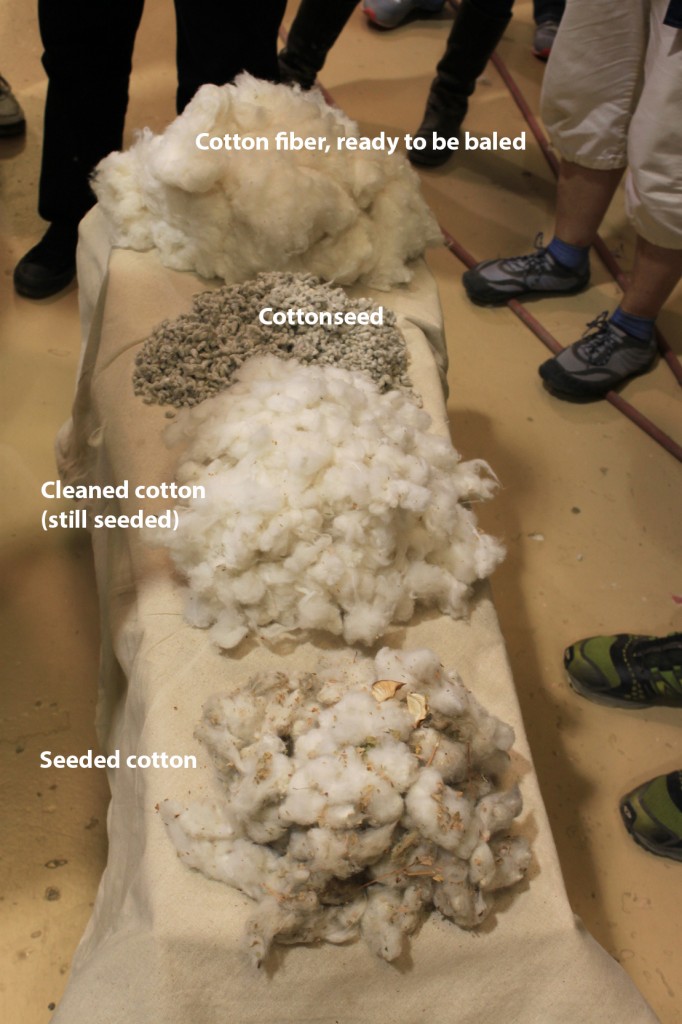

The cotton in the modules is called ‘seeded cotton’; the modules will be trucked to a gin where the seed and fiber are separated.

These modules are waiting at the cotton gin to be processed. These modules are round because they were made by a newer model of cotton harvester.

Each module is coded with a number that identifies the origin of the cotton, including what field it was grown on. This permanent bale identification code will remain with the cotton throughout the ginning process for easy identification and tracking to the spinner.

The modules are fed into the gin. They will first go through dryers to reduce moisture, and then through cleaning equipment to remove dirt, leaves and other impurities. Then machines will remove the seeds and compress the fibers into bales.

The raw cotton is conveyed by air through pipes around the facility.

The bales each weigh about 500 lbs each.

Here is a display of cotton in the various stages throughout the ginning process.

Cottonseed represents about 60% of the cotton harvest by weight.

Cottonseed oil is used in processed foods, salad dressings, marinades and baked goods.

However, the cottonseed in California is mostly used for cattle feed.

The Sustainable Cotton Project also works to connect growers with the fashion and textile industry to serve the emerging sustainable fashion industry. “Cleaner Cotton is grown with reduced toxicity and non-genetically modified seed”, said Lynda Grose, fashion sustainability expert and assistant professor at San Francisco’s California College of the Arts. “The U.S. public is looking to bolster the domestic economy. A Cleaner Cotton grown and sewn in the U.S. is a great multiple message for any American retailer.”

With the costs of farming continuing to rise, and tougher regulations on agricultural chemicals and irrigation runoff, there is a growing recognition among farmers of the need to try something different. “Cleaner Cotton really opened up my eyes”, says Chad Crivelli, one of the Sustainable Cotton Project farmers. “Farmers can still make a profit growing cotton and reduce chemicals. That’s a great feeling. It’s a very good concept. It does work.”

FOR MORE INFORMATION:

- Click here to visit the webpage for the Sustainable Cotton Project.

- Click here for information on California cotton.